Aluminum

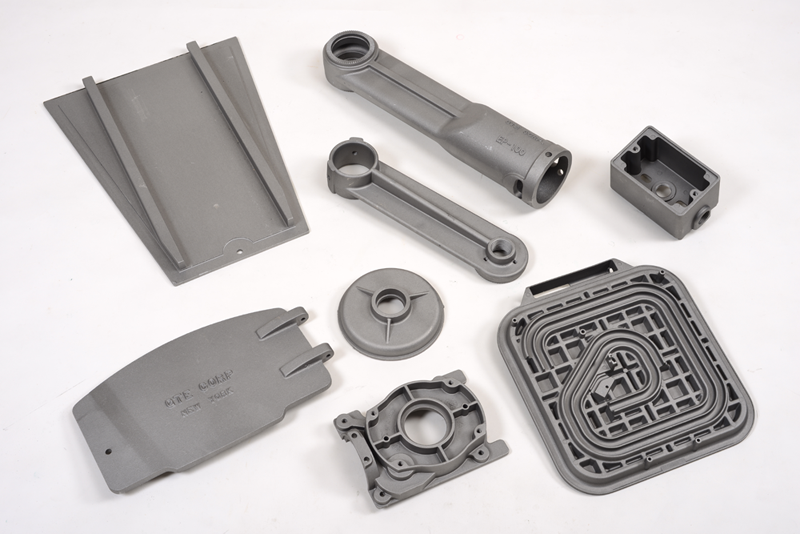

LIAN CHANG provides all kinds of die casting parts, we are specialized in brass alloy, aluminum alloy and zinc alloy…etc. We can also provide customized design and manufacturing, please contact us if you need professional die casting.

The aluminum alloy materials are AA#360, A360,380, A380, and 384 or JIS ADC3, ADC6, ADC10 and ADC12.

Some European Standard die cast aluminum alloys are also available.

Die-casting aluminum alloys used in the type and number

| Number | Reference | |||

|---|---|---|---|---|

| Alloy | Similar alloys | Characteristics of the alloy | Case | |

| ADC 1 | AI-Si | AA A 413.0 |

Corrosion resistance, die casting, less resistant to pressure | Vehicle body frame, the front wheel, automatic bread lined |

| ADC 3 | AI-Si-Mg | AA A 360.0 |

Impact value and good pressure resistance, corrosion resistance whole family in an almost the same as casting pressure | Flywheel car cover, motorcycle crankcase, automotive flywheels, outboard propeller vane |

| ADC 5 | AI-Mg | AA 518.0 |

Corrosion resistance, good high impact value of elongation, the casting is bad | Agricultural arm, outboard propulsion device Vane, fishing tackle, wrenches, reel, reel device |

| ADC 6 | AI-Mg | AA 515.0 |

Corrosion resistance and the fifth are good, the casting than the fifth species a little better | Motorcycle brake handles, outboard propulsion device vane axle box, water pump, the disk device |

| ADC 10 | AI-Si-Cu | AA B 380.0 |

Mechanical properties, cutting and casting are excellent | Automobile carburetor, cylinder block, cylinder head, motorcycle shock absorber, engine crankcase, side cover, cylinder block, agricultural gearbox, crankcase cover, VCR, Block, photographic body, the body of power tools, cover, motorupper and lower lid rotor, car rack, and head and body, tackle body, the hinge device, gas regulator, distributor parts |

| ADC 10 Z | AI-Si-Cu | AA A 380.0 |

Almost the same, and the tenth type casting embrittlement and corrosion resistance is poor | |

| ADC 12 | AI-Si-Cu | AA 383.0 |

Mechanical properties, cutting and casting are excellent | |

| ADC 12 Z | AI-Si-Cu | AA 383.0 |

And 12 kinds of the same pillar shape mode crack resistance, the Ten Level casting good | |

| ADC 14 | AI-Si-Cu | AA B390.0 |

Instant-resistant mold, good casting, pressure and so excellent, poor elongation | Car parts, clutch housing assembly with the pump body, locomotive buried |

Die-casting aluminum alloys used in chemical composition

| Cu | Si | Mg | Zn | Fe | Mn | Ni | Sn | Al | |

|---|---|---|---|---|---|---|---|---|---|

| ADC 1 | 1.0以下 | 11.0-13.0 | 0.3以下 | 0.5以下 | 1.3以下 | 0.3以下 | 0.5以下 | 0.1以下 | Other |

| ADC 3 | 0.6以下 | 9.0-10.0 | 0.4-0.8 | 0.5以下 | 1.3以下 | 0.3以下 | 0.5以下 | 0.1以下 | Other |

| ADC 5 | 0.2以下 | 0.3以下 | 4.0-8.5 | 0.1以下 | 1.8以下 | 0.3以下 | 0.1以下 | 0.1以下 | Other |

| ADC 6 | 0.1以下 | 1.0以下 | 2.5-4.0 | 0.4以下 | 0.8以下 | 0.4-0.6 | 0.1以下 | 0.1以下 | Other |

| ADC 10 | 2.0-4.0 | 7.5-9.5 | 0.3以下 | 1.0以下 | 1.3以下 | 0.5以下 | 0.5以下 | 0.3以下 | Other |

| ADC 10 Z | 2.0-4.0 | 7.5-9.5 | 0.3以下 | 3.0以下 | 1.3以下 | 0.5以下 | 0.5以下 | 0.3以下 | Other |

| ADC 12 | 1.5-3.5 | 9.6-12.0 | 0.3以下 | 1.0以下 | 1.3以下 | 0.5以下 | 0.5以下 | 0.3以下 | Other |

| ADC 12 Z | 1.5-3.5 | 9.6-12.0 | 0.3以下 | 3.0以下 | 1.3以下 | 0.5以下 | 0.5以下 | 0.3以下 | Other |

| ADC 14 | 4.0-5.0 | 16.0-18.0 | 0.45-0.65 | 1.5以下 | 1.3以下 | 0.5以下 | 0.3以下 | 0.3以下 | Other |

Die-casting aluminum alloy casting and other features

| Solidification temperature range ( ℃ ) | Pressure made of die-casting products | A variety of other features | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Heat between the brittle | Tightness | Mold filling capacity | Non-modal melting with sexual | Corrosion resistance | Machinability | Abrasive | Electrical number of sexual | Anodized appearance | The strength of the skin mode. Chemical acidification |

High-temperature strength | |||

| General use | ADC 1 | 570-580 | 1 | 1 | 1 | 2 | 3 | 4 | 5 | 3 | 5 | 3 | 3 |

| ADC 10 | 540-590 | 2 | 2 | 2 | 1 | 4 | 3 | 3 | 1 | 3 | 5 | 2 | |

| ADC 12 | 520-580 | 2 | 2 | 1 | 3 | 4 | 3 | 3 | 2 | 4 | 4 | 2 | |

| Special use | ADC 3 | 580-600 | 1 | 1 | 1 | 3 | 2 | 3 | 3 | 1 | 3 | 3 | 1 |

| ADC 5 | 540-620 | 5 | 5 | 4 | 5 | 1 | 1 | 1 | 5 | 1 | 1 | 4 | |

| ADC 14 | 510-650 | 4 | 4 | 1 | 2 | 3 | 5 | 5 | 3 | 5 | 5 | 3 | |

A variety of die-casting aluminum alloys used in the physical properties of

| Project | Alloy types | General alloys | Special alloys | |||||

|---|---|---|---|---|---|---|---|---|

| Number | ADC 1 | ADC 10 | ADC 12 | ADC 3 | ADC 5 | ADC 14 | ||

| The nature of the physical | Proportion | 2.55 | 2.71 | 2.70 | 2.63 | 2.57 | 2.75 | |

| Melting point | K | 858 | 883 | 835 | 873 | 913 | 923 | |

| Specific heat | J/gk | 0.96 | 0.96 | 0.96 | 0.96 | 0.96 | ||

| Coefficient of thermal expansion | (180-300℃)K | 21X10 | 22X10 | 22X10 | 22X10 | 25X10 | 19.2X10 | |

| LACS% | 31 | 23 | 23 | 29 | 24 | |||

Die-casting aluminum ingot type and number

| Number | Reference | |

|---|---|---|

| Alloy | Correspond JIS HS302 | |

| AD 1.1 | AI-Si | ADC 1 |

| AD 1.2 | ||

| AD 3.1 | AI-Si-Mg | ADC 3 |

| AD 3.2 | ||

| AD 5.1 | AI-Mg | ADC 5 |

| AD 5.2 | ||

| AD 6.1 | AI-Mg | ADC 6 |

| AD 6.2 | ||

| AD 10.1 | AI-Si-Cu | ADC 10 |

| AD 10.2 | ||

| AD 10 Z.1 | AI-Si-Cu | ADC 10 Z |

| AD 12.1 | AI-Si-Cu | ADC 12 |

| AD 12.2 | ||

| AD 12 Z.1 | AI-Si-Cu | ADC 12 Z |

| AD 14.1 | AI-Si-Cu | ADC 14 |

Applications

Lock parts Lighting fixtures Hardware parts Electronic parts Bicycle / motorcycle / car spare parts

OEM parts and components according to customers' specifications

Cast to finish

CNC machining;

drilling / tapping / broaching / reaming / sanding / polishing / buffing / blast cleaning / vibrating / thermo-debarring / assembly / packaging / outside chemical finishing and painting.

LIAN CHANG Casting Inc.

Our company is ISO 9001 certified

Address | No.1 Shi 3rd Road, Yangmei, Taoyuan 32657, Taiwan.

Tel | +886-3-496-3377

Fax | +886-3-496-2288

E-mail | abzm@ms34.hinet.net 、yicholin@gmail.com